Compared with the equivalent material manufacturing process and the subtractive material manufacturing process, 3D printing has many advantages, and many articles have carried out detailed analysis and elaboration. The author believes that compared with traditional manufacturing processes, 3D printing has the following three main advantages:

- Design space is unlimited. For objects with complex geometric structures (such as objects with very complex topological structures or cavity structures inside), traditional manufacturing processes cannot be processed, and the objects need to be decomposed and separately processed and reassembled. 3D printing, on the other hand, decomposes objects into layer-by-layer 2D regions, so there is no problem in processing arbitrarily complex objects, and the processing accuracy only depends on the smallest material particles that the printer can output. This is the biggest advantage that 3D printing brings to us, allowing designers to design arbitrarily complex geometric shapes with unlimited design space. It is this advantage that gives us a large number of problems to be solved in geometric design and optimization, which will be described in detail later.

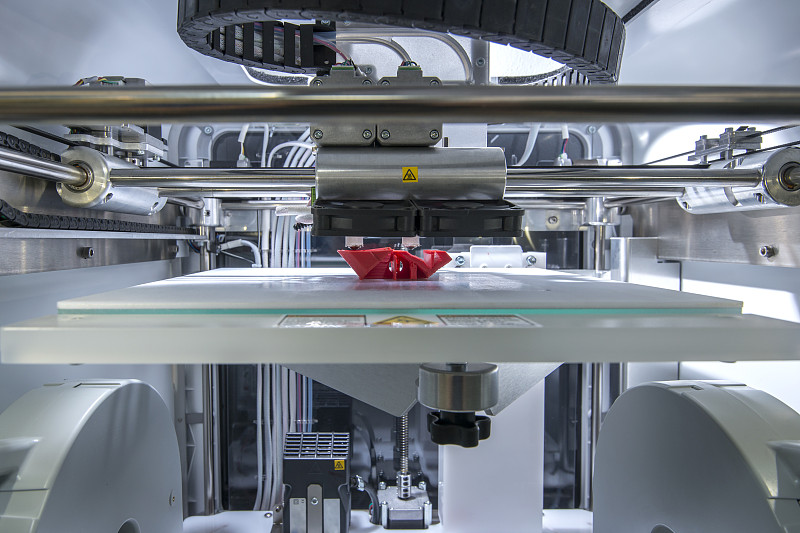

- Zero skill manufacturing. Traditional manufacturing process equipment is bulky and expensive and requires high skills to operate. And 3D printers (such as FDM 3D printers) are small and cheap, and some have entered the home, which is easy and convenient to use; compared with expensive casting molds, 3D printing only requires a digital file to form. Therefore, through 3D printing, individual design and customization of products can be easily realized, which greatly shortens the development time of products. This advantage gives us non-mechanical researchers who can also conduct related research on geometry, structure, materials, etc., which greatly deepens and expands related research problems in manufacturing.

- Unlimited combinations of materials. Multi-jet 3D printers can print combinations of multiple materials. Through stacking and combination of materials, printed items have physical and mechanical properties that differ from a single material. Therefore, through the combination of different materials, “new materials” with different properties can be produced. This advantage provides us with the ability to control the physical, mechanical and structural properties of objects by controlling the distribution of materials, thereby enabling the creation of diverse objects and increasing product flexibility. **

Of course, as a young molding process, 3D printing still has many shortcomings, such as slow molding time, low precision, few types of materials, and inability to mass-produce. At this stage, the actual use of 3D printing still belongs to the category of rapid prototyping, that is, the manufacture of product prototypes for enterprises before the production of formal products, also known as prototypes in the industry. Therefore, at this stage, the 3D printing molding process exists as a complementary method to the traditional manufacturing process, and it will take time to become a mainstream manufacturing technology. But we must believe that the pursuit of technology by human beings is infinite. With the continuous progress of research and development of 3D printing equipment and printing materials, 3D printing technology will be more and more widely used.

From another perspective, 3D printing technology has allowed manufacturing to move from factories to homes, spawning a large number of individual designers (ie makers), and stimulating infinite creative design possibilities.