As the methods and principles of the traditional manufacturing industry have been completely changed, 3D printing, as a key core technology, has become a technical measure for the advancement of manufacturing in various countries. According to the “Wohlers Report 2018” recently released by Wohlers Associates, a well-known 3D printing consultancy, the additive manufacturing industry as a whole grew by 21% in 2017, with a market value of more than $1.25 billion. Industry figures show that the 3D printing market will be worth as much as $21 billion by 2020.

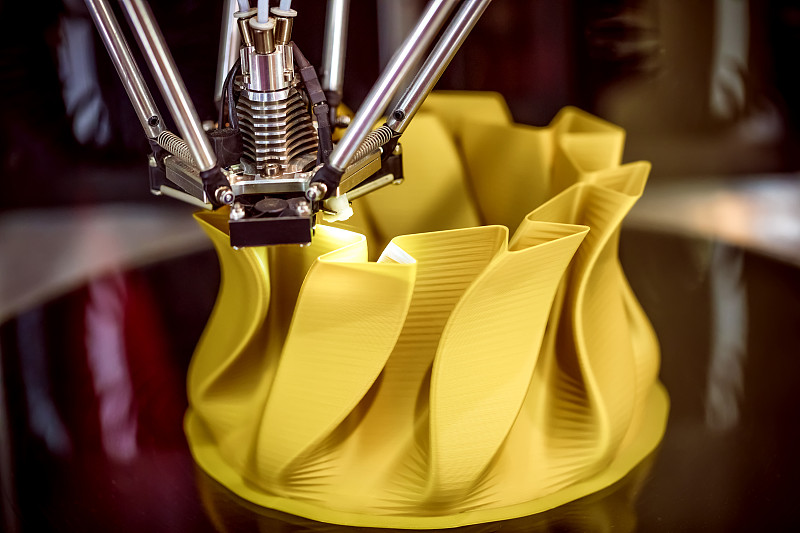

3D printing manufacturing technology is mainly composed of three elements: precise three-dimensional design; powerful molding equipment; materials that meet product performance and molding process.

At present, there are about 200 kinds of 3D printing materials, which usually have extremely high requirements for heat resistance, flexibility, stability and sensitivity, and are specially developed for 3D printing equipment and processes.

It can be seen that 3D printing materials, which are a key part of the 3D printing storm sweeping the world today, are undoubtedly helping to stir the storm. As the “ink” of 3D printing, the development of 3D printing materials is difficult and costly, and it is still a constraint to the construction of the 3D printing ecosystem.

As the saying goes, “A smart woman can’t cook without rice”, the importance of 3D printing materials to 3D printing is self-evident! Today, let’s take a good look at these 3D printing materials.

Engineering plastics As the most widely used type of 3D printing materials, engineering plastics account for more than 90% of commercial 3D printing materials. They are used in FDM equipment and are plastics with excellent strength, impact resistance, heat resistance, hardness and aging resistance. It mainly includes thermoplastic materials and thermosetting materials. At present, the common engineering plastics mainly include the following categories:

ABS: One of the hottest FDM thermoplastics today, usually in filament form; with good hot melt and impact strength, it is the engineering plastic of choice for 3D printing by fused deposition. The advantage is that the printed parts are mechanically strong and stable. Also, it can be used with soluble support materials. A variety of colors can be selected, and even custom colors can be made. For example, Stratasys’ ABS plus material can provide nine color choices such as ivory, white, and black with the assistance of FDM technology.

PC: White engineering plastic that can be combined with FDM technology to create durable models, tools or final product parts. Compared with ABS plastic, PC material has the advantages of better strength, high temperature resistance, impact resistance, etc., so it can be used as the final component for the application of super-strong engineering products. Samples made of PC materials can be directly assembled and used, and are widely used in automobile manufacturing, aerospace, medical equipment and other fields.

PA: high mechanical strength, and has certain flexibility, heat resistance, friction resistance. Stratasys’ FDM Nylon 12 has excellent strength properties, fatigue resistance, and resistance to moderately aggressive chemicals for re-closing, snap-in and vibration-resistant parts, while Stratasys’ FDM Nylon 6 also has superior performance over other The strength and toughness of thermoplastics to withstand rigorous functional testing makes them ideal for product manufacturers and development engineers in the automotive, aerospace, consumer and industrial manufacturing industries.

photosensitive resin

Due to its fast curing speed, the photosensitive resin has excellent surface drying properties, and the product has a smooth appearance after molding, which can be transparent to translucent and frosted. Because of its good liquid fluidity and instant light curing properties, liquid photosensitive resin has become the first choice for 3D printing consumables for high-precision product printing. There are currently three main categories:

Oligomers: low-molecular polymers containing unsaturated bonds, there are many types, and various types of acrylic resins are the most common. Oligomer is the most basic material in photocurable materials, which determines the basic physical and chemical properties of photosensitive resin such as viscosity, hardness, elongation at break, etc.

Reactive diluent: is a small molecule solvent containing double bonds. The reactive diluent adjusts the viscosity of the system, reduces the viscosity of the oligomer, and avoids clogging of the nozzle due to excessive viscosity. The reactive diluent also participates in the photocuring reaction, which affects the kinetics of the polymerization reaction, the degree of polymerization, and the physical properties of the cured product.

Photoinitiator: The most critical component determines the quality of the photocurable material and the speed of the photocuring reaction. It can be divided into ultraviolet initiators and visible light initiators according to the energy of initiating radiation. Since UV photoinitiators have the advantage of being stable in storage, all photoinitiators used in the 3D printing market today are UV photoinitiators.

metallic material 3D printing metal materials exist in the form of metal powder, metal foil and metal wire. The market share of metal materials is small at this stage, but the expansion rate is the fastest.

Metal materials can be used in industrial-grade 3D printers such as selective laser sintering (SLS), direct metal laser sintering (DMLS), and electron beam melting (EMB). If metal materials are added to some engineering plastic materials (such as ABS), wires with certain metal properties can be made suitable for FDM models.

In the process of 3D printing metal materials, factors such as solid-liquid phase transition, surface diffusion and heat conduction of the metal need to be considered, and the shape of the metal powder directly affects the quality of the 3D printed product. Common metal materials today include titanium alloys, stainless steels, cobalt-chromium alloys, and aluminum alloys. Gold, silver and other precious metal powder materials are occasionally used to print jewelry or artwork.

Ceramic material Aluminum silicate ceramic powders can be used to 3D print ceramic products, generally in powder form, and are typically used in selective laser sintering (SLS) printers. Ceramic powder for 3D printing is a mixture of ceramic powder and a certain binder powder.

The ratio of ceramic powder and binder powder will directly affect the performance of ceramic parts. The greater the amount of binder, the easier sintering, but the shrinkage of the parts is relatively large during the post-processing process, which will affect the dimensional accuracy of the parts. When the amount of binder is small, it is difficult to sinter and form.

Ceramic materials have the advantages of high strength, high temperature resistance and corrosion resistance, and have the potential to be used in aerospace and automotive fields. At the same time, ceramic materials can be selected in many colors, and can print products with realistic shapes and rich colors, which are ideal for handicrafts, construction and bathroom products.

Biopolymers Bio-3D printing materials mainly include scaffold materials and direct cell printing materials. Scaffolding 3D printing materials need to meet: good biocompatibility, non-toxic to cells and the body; good biodegradation characteristics, can be completely degraded and absorbed by the body or excreted from the body; good mechanical properties, with certain mechanical strength and plasticity , the structure can remain stable for a long time, with high porosity; good surface compatibility is conducive to the adhesion and growth of cells on the surface of the material. Mainly divided into the following categories:

PLA: The best starting material for 3D printing, with a variety of translucent colors and glossy textures. It is derived from renewable resources – corn starch and sugar cane, non-toxic and tasteless, and is an environmentally friendly plastic that can be degraded.

PETG: It has excellent thermoformability, toughness and weather resistance, short thermoforming cycle, low temperature, high yield, and has the advantages of PLA and ABS.

PCL: is a biodegradable polyester with a low melting point, often used for special purposes such as drug delivery devices, sutures, etc. It also has shape memory properties. In the medical field, it can be used to print heart stents, etc.

Other 3D printing materials Carbon fiber material is an emerging 3D printing material, which is five times stronger than steel but only 1/3 of its weight, and has the advantages of high temperature resistance and corrosion resistance.

Conductive printing materials are a type of thermoplastic material that can be used to manufacture 3D printed products with electronic or mechanical functions, such as circuit boards, flashlights, and wearable lighting devices.

Through the above analysis You should know more about 3D printing materials! We also believe that with the continuous development and innovation of new material technologies, there will be more and better practical 3D printing materials in the future.